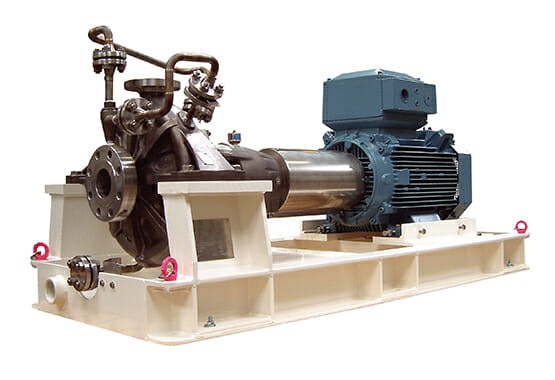

API 610 OH2 Pumps

API 610 OH2 12th edition Process Pump for the Oil & Gas Industry.

Amarinth API 12th edition Process Pump A Series petrochemical process pumps are designed and manufactured for a number of applications including LPG, fuel transfer, produced water and export duties. The pumps are typically found in the oil & gas production and refinery industries, though they can be used for other applications such as seawater and condensate duties. A Series pumps are designed for low NPSH applications and all have independently verified, full ATEX pump compliance.

Download Brochure

Using modern computer aided design software the process pumps are designed as a heavy duty, minimal wear, long life pump. Conceived as a modular design, with a number of options available, ensures full compliance with a customer's exact requirements and specifications. A fully API compliant heavy duty baseplate helps achieve low vibration and noise levels which in turn extends the pump's life and ensures maximum running time. A 'space saving' reduced footprint baseplate is also available for use where space is at a premium.

The OH2 Pumps can be fitted with a variety of proprietary components (i.e. seals, motors and couplings) from all the major manufacturers to cater for customers site preferences. Double mechanical seal arrangements can be fitted with a seal support system attached. This can be supplied by Protect System, which is designed and manufactured by Amarinth, or if required another manufacturers' seal support system can be provided for Amarinth to install and fit.

To complete the package a full range of standard material options from SG iron and stainless steel, to super duplex and hastelloy are available to match your process fluid. NACE and NORSOK compliant materials are also available. Standard documentation packs including manufacturing data books, material certification, installation and operating manuals are available to suit the application. Performance testing to OH2 / ISO 13709 and various NDE (non destructive examination) and NDT (non destructive testing) options are offered to ensure full compliance to our customer's specifications. Alternative bespoke packages can be tailored to fit your exact requirements.

For more information about this product please get in touch using one of the methods below.

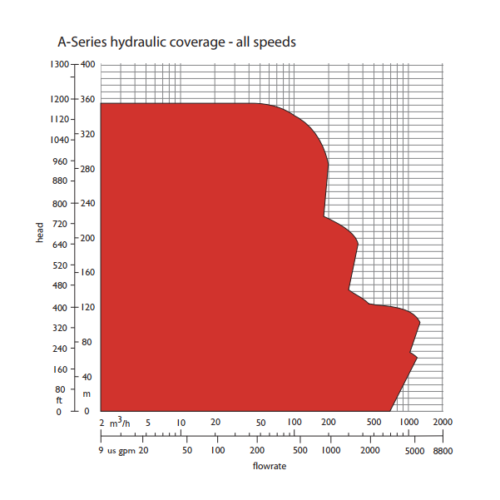

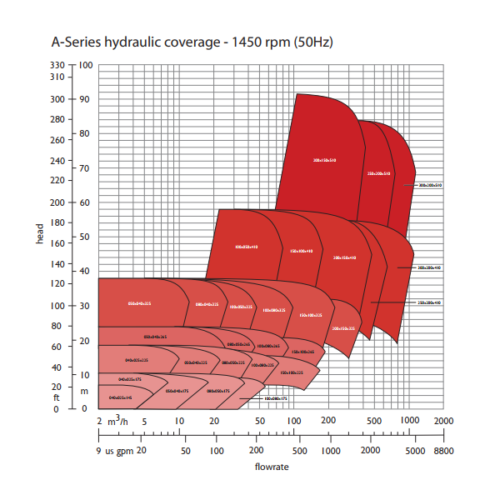

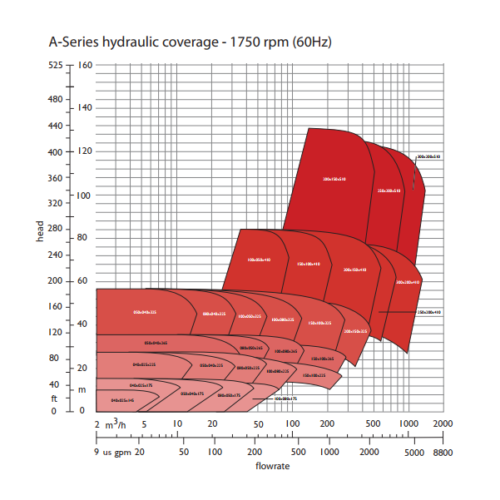

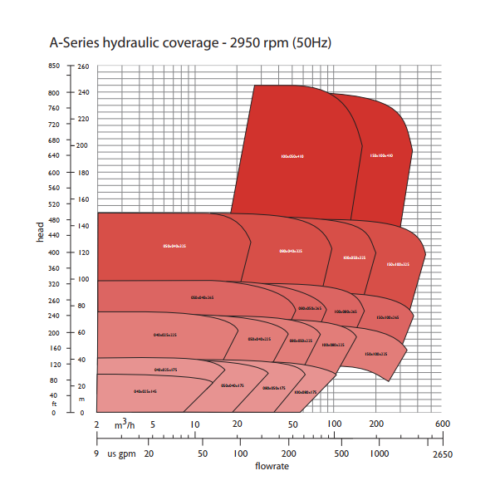

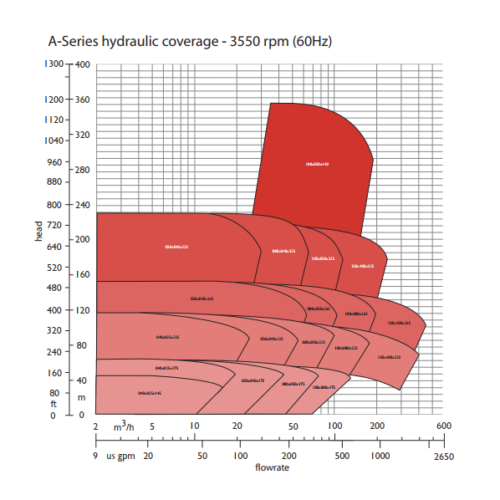

Hydraulic Performance

Amarinth A Series pumps can be fitted with fixed or variable speed drivers from any manufacturer. The overall A Series hydraulic coverage chart is shown on the left. More detailed hydraulic coverage charts list individual pump designations at 2 pole & 4 pole speeds. Specific duty curves will be provided with all quotations.

Use the slider at the bottom of the images to select the hydraulic coverage chart you're interested in & then launch the relevant pdf to review the coverage charts in more detail.

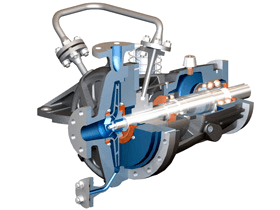

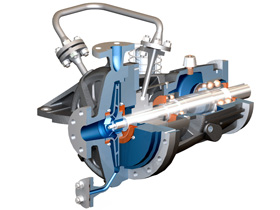

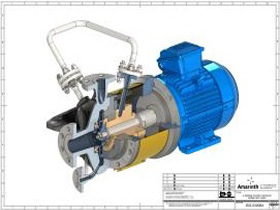

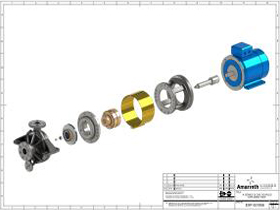

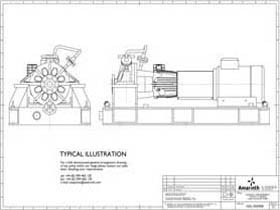

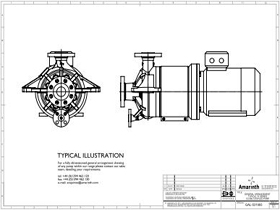

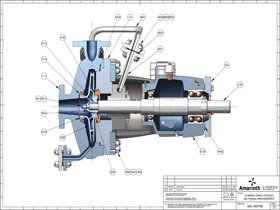

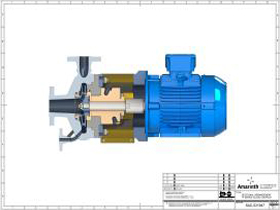

Drawings & Visualisations

A number of images in various pump configurations are provided to help you visualise our A Series product including:

- Isometric view

- Exploded view

- General arrangement

- Sectional arrangement

Select an image below using the slider at the bottom and then launch the relevant PDF.

Specifications

| General description | A range of API 610 OH2 single stage, centreline mounted centrifugal end suction pumps with centreline discharge manufactured in a variety of alloys. |

| Construction | Back pullout design with metal to metal fits |

| Design methodology | Advanced computer techniques including 3D modelling, FEA & CFD |

| Design standards | API 610 12th edition / ISO 13709:2009 |

| Design pressure rating | 51.8 bar g @ 20°C |

| Suction pressure rating | 20 bar g (standard construction) |

| Temperature rating | -40°C to 200°C (standard construction) |

| Design temperature | 150°C (standard construction) |

| Flow rate | Up to 1100m³/h |

| Differential head | Up to 225m |

| Speed | Up to 3600 rpm |

| Configurations | Long coupled pump |

| Frame sizes | 040x025x145 to 250x200x510 |

| Design life | 25 years (3 years uninterrupted operation) |

Materials

Amarinth A Series pumps are available in a variety of materials as standard which include the following pump / impeller combinations.

Other alloys, including NACE compliant materials are available on request and our foundries are NORSOK approved.

In addition we offer a full range of NDE & NDT options along with full component traceability to ensure compliance to your exact requirements.

| Materials | Casing | Impeller |

|---|---|---|

| A8 - SS 316L / SS 316L | ASTM A351 CF 3M | ASTM A351 CF 3M |

| I1 - Cast iron / Cast iron | ASTM A278 Class 30 | ASTM A278 Class 30 |

| S8 - Carbon Steel / SS 316L | ASTM A216 WCB | ASTM A351 CF 3M |

| S6 - Carbon Steel / 12% Cr SS | ASTM A216 WCB | ASTM A217 Gr CA15 |

| D1 - Duplex SS / Duplex SS | ASTM A890 Gr 4A (UNS J92205) | ASTM A890 Gr 4A (UNS J92205) |

| D2 - Super Duplex SS / Super Duplex SS | ASTM A890 Gr 6A (UNS J93380) | ASTM A890 Gr 6A (UNS J93380) |

| Hastelloy B / Hastelloy B | ASTM A494 Gr N 7M | ASTM A494 Gr N 7M |

| Hastelloy C / Hastelloy C | ASTM A494 Gr CW 12MW | ASTM A494 Gr CW 12MW |

| Monel / Monel | ASTM A494 Gr M35 1 | ASTM A494 Gr M35 1 |

| Titanium / Titanium | ASTM B367 Gr C2 | ASTM B367 Gr C2 |

Isometric - long coupled

Isometric - long coupled

Isometric - close coupled

Isometric - close coupled

Exploded view- long coupled

Exploded view- long coupled

Exploded view- close coupled

Exploded view- close coupled

GA - long coupled

GA - long coupled

GA - close coupled

GA - close coupled

GA - bareshaft unit

GA - bareshaft unit

SA - long coupled

SA - long coupled

SA - close coupled

SA - close coupled