Girdlestone Industrial – SSM/SSD Pump

Girdlestone manufactured this range of centrifugal pumps to cover the low flow end of the pumping spectrum, with robust reliability needed for the more difficult pumping needs of industry – particularly with the chemical, pharmaceutical and marine markets in mind.

Amarinth’s equivalent to the Gridlestone SSM and SSD ranges is fully interchangeable both hydraulically and dimensionally requiring no pipework modifications and provides many more years of reliable service from this proven workhorse.

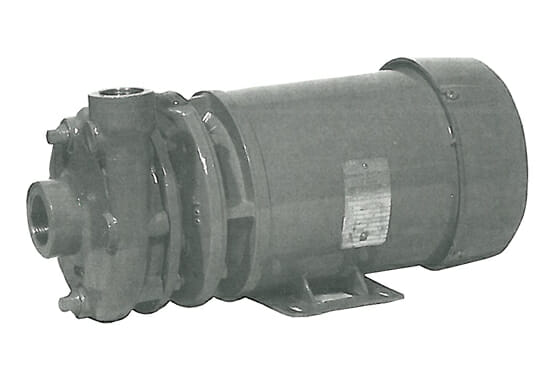

The units are available in both close-coupled and direct coupled formation, with a variety of mechanical sealing options.

Materials of construction include stainless steel, bronze, cast iron, and a selection of sophisticated alloys, for highly corrosive or erosive applications.

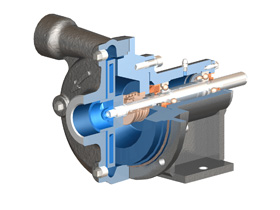

Construction is kept simple and incorporates the back pull out principal now established as the ‘norm’ for pumps designed with the maintenance engineer in mind.

Using modern computer aided design software the pumps are designed as a light to medium duty, minimal wear, long life pump. This original Girdlestone design has been in use for many decades and is a well proven, reliable workhorse. The Amarinth S Series replacement is aimed at customers who want the same reliability and minimum disruption when a new replacement is required for their existing Girdlestone pump.

To complete the package a full range of standard material options including cast iron, stainless steel and gunmetal are available to match your process fluid. Standard documentation packs including data sheets, material certification, installation and operating manuals are available to suit the application. Performance testing to BS EN 25199 / ISO 5199 and various NDE (non destructive examination) and NDT (non destructive testing) options are offered to ensure full compliance to our customer's specifications. Alternative bespoke packages can be tailored to fit your exact requirements.

For more information about this product please get in touch using one of the methods below.

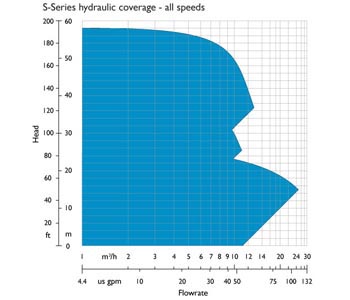

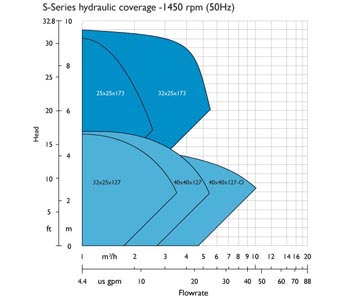

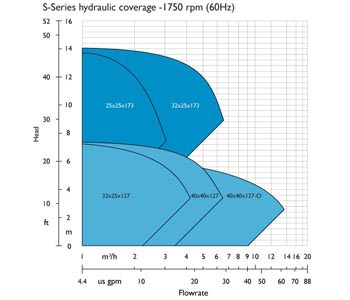

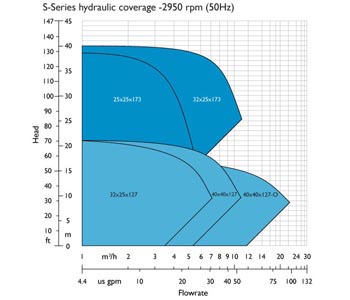

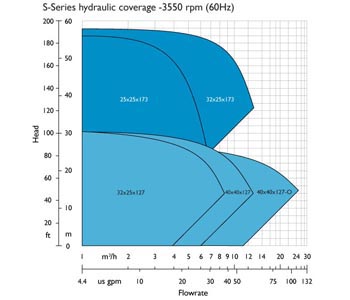

Hydraulic Performance

Girdlestone SSM / SSD pumps can be fitted with fixed or variable speed drivers from any manufacturer. More detailed coverage charts list individual pump designations at fixed speeds.

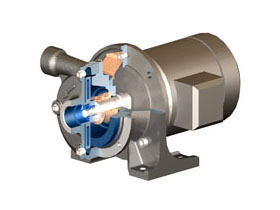

Drawings & Visualisations

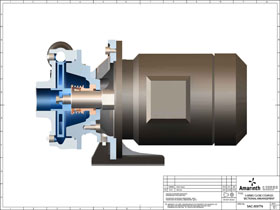

The image below shows a three quarter Isometric cut-out of a long coupled S Series pump. You can also display the following images:

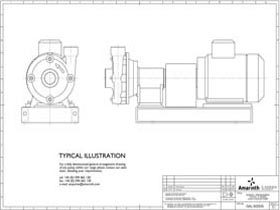

General arrangement drawing

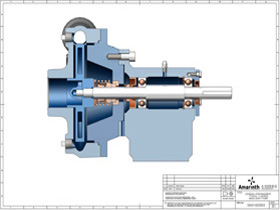

Sectional arrangement drawing

Specifications

| General description | A range of single stage centrifugal end suction pumps with tangential discharge manufactured in a variety of alloys. All pumps and individual components are fully interchangeable with the equivalent Girdlestone SSD / SSM series units. |

| Construction | Back pullout design with machined abutments |

| Design methodology | Advanced computer techniques including 3D modelling, FEA |

| Design standards | ATEX EC-Directive 94/9/EC (close coupled versions only) |

| Design pressure rating | 10 bar g @ 20°C |

| Suction pressure rating | 7.5 bar g (long coupled) |

| Temperature rating | -5°C to 120°C (long coupled) |

| Design temperature | 150°C (standard construction) |

| Flow rate | Up to 20m³/h |

| Differential head | Up to 55m |

| Speed | Up to 3600 rpm |

| Configurations | Long coupled pump |

| Frame sizes | 025x025x173 to 040x040x127 |

| Design life | 15 years (2 years uninterrupted operation) |

Materials

Girdlestone SSM / SSD pumps are available in a variety of materials as standard which include the following pump / impeller combinations;

| Materials | Casing | Impeller |

|---|---|---|

| Cast Iron / Cast Iron | BS EN 1561 Gr EN-GJL-250 | BS EN 1561 Gr EN-GJL-250 |

| Cast Iron / Gun metal | BS EN 1561 Gr EN-GJL-250 | BS EN 1982 CC492K-GS |

| Cast Iron / Stainless steel 316 | BS EN 1561 Gr EN-GJL-250 | ASTM A744 CF-8M |

| Stainless steel 316 / Stainless steel 316 | BS 3100 316 C12 | ASTM A744 CF-8M |

| Gunmetal / Gunmetal | BS 1400 LG2 | BS EN 1982 CC492K-GS |

| Titanium / Titanium | ASTM B367 Gr C-2 | ASTM B367 Gr C-2 |

Isometric - long coupled

Isometric - long coupled

Isometric - close coupled

Isometric - close coupled

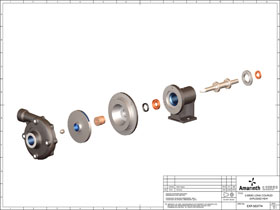

Exploded view- long coupled

Exploded view- long coupled

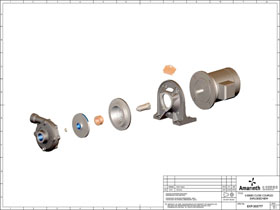

Exploded view - close coupled

Exploded view - close coupled

GA - long coupled

GA - long coupled

GA - close coupled

GA - close coupled

GA - bareshaft unit

GA - bareshaft unit

SA - long coupled

SA - long coupled

SA - close coupled

SA - close coupled