COMPACT CONDENSATE RECOVERY UNITS - M UNIT

Amarinth M Unit Condensate Recovery Units perform a critical role within the overall condensate recovery system, ensuring that the maximum latent energy is retained by returning the condensate to the boiler. They are typically used in industrial buildings such as factories and hospitals.

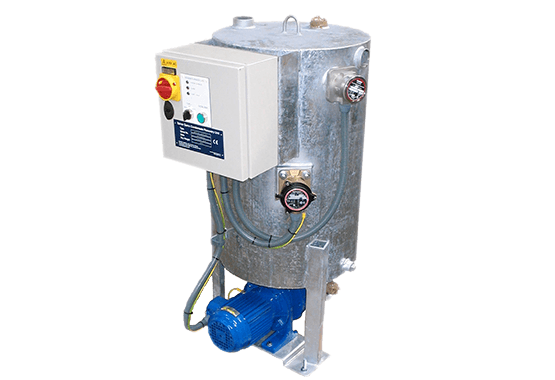

M Unit Condensate Recovery Units are compact and incorporate a control panel and a low NPSH pump to minimise space – both footprint and height.

Download Brochure

For more information about this product please get in touch using one of the methods below.

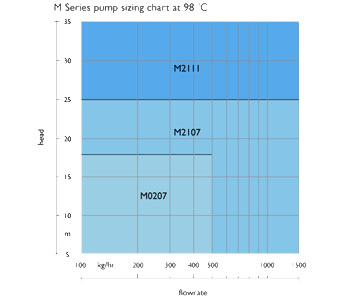

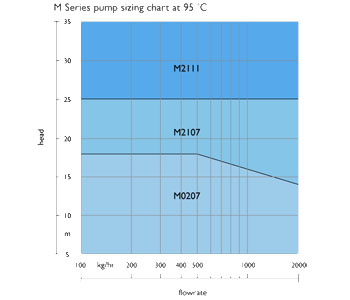

CRU Sizing Charts

Amarinth M unit Condensate Recovery Units are designed for relatively small loads. Units are sized based on the head and flow required to get the condensate back to the boiler, along with the operating temperature as this affects the NPSH required by the pump - either 98°C or 94°C.

Select the coverage chart you're interested in & then launch the relevant pdf to review the options in more detail.

Specifications

Compact packaged Condensate Recovery Unit incorporating a vertical galvanised receiver with single close coupled motor pump and control gear pre wired ready for use

| Construction | Steel receiver with integral control unit and pump |

| Design methodology | Advanced computer techniques including 3D modelling, FEA & CFD |

| Design pressure rating | Vented operation |

| Temperature rating | 120°C (standard construction) |

| Operating temperature | Up to 98°C |

| Flow rate | Up to 2,000kg/h |

| Differential head | Up to 35m |

| Speed | Up to 3600 rpm |

| Control gear | Float operated magnetic level switch linked to control panel |

| Configurations | Simplex unit |

| Design life | 20 years (2 years uninterrupted operation) |

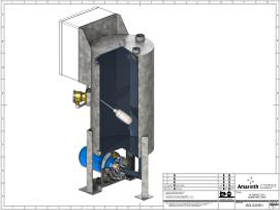

Isometric - M Series unit

Isometric - M Series unit

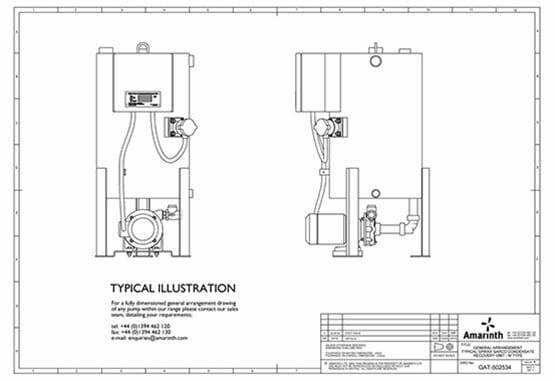

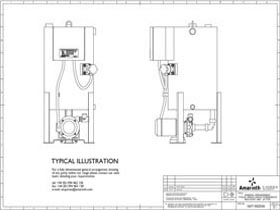

GA - M Series unit

GA - M Series unit

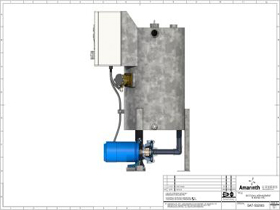

SA - M Series unit

SA - M Series unit