Amarinth’s scalable pump seal support system ATUs are ideally suited to short lead time contracts

FOR IMMEDIATE RELEASE – 27th February 2019

Amarinth, a leading company specialising in the design, application and manufacture of centrifugal pumps and associated equipment to the Oil & Gas, petrochemical, chemical, industrial and power markets, now offers a scalable, configurable range of pump seal support system Automatic Top Up Units which are designed and manufactured in-house and can be completed to meet short lead time contracts

Automatic Top Up Units (ATUs) enable the automatic refilling or topping up of Plan 53B barrier systems which maintain a constant barrier fluid supply through the seal system to the pump shaft seal, preventing leakage of the process fluid to atmosphere. Although ATUs are available from other suppliers, the long lead times of these units (typically 32 to 40 weeks) does not meet many of today’s shorter pump lead times which Amarinth is experiencing, especially with the recent upturn in pump orders being placed by the Oil and Gas industry.

With no definitive API standard for ATUs, end-user specifications define the design, construction and test of these units which means every package has historically been bespoke, significantly extending lead times. Drawing on its decades of industry experience and knowledge of end-user specifications (for example Shell DEP, ADCO, Norsok, BP DGS and Petronas), Amarinth has therefore developed a comprehensive and modular approach that is suitable for a broad range of applications and end-user needs.

The ATUs, which are all manufactured in-house, are scalable and configurable enabling them to be completed to suit short lead time contracts, which can often be under 22 weeks, whilst continuing to meet stringent customer specifications and restrictive customer vendor lists for all instrumentation, valves and controls.

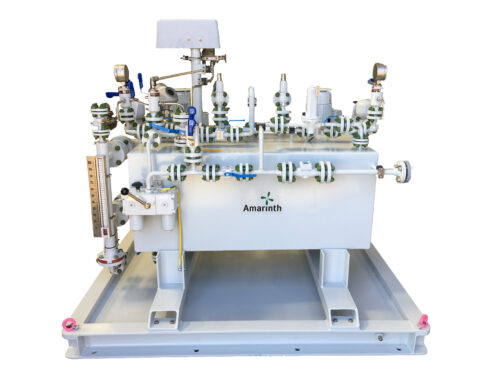

ATUs can be assembled to suit anything from a single pump to multiple charging pumps and in addition to the number of pumps, the system is readily scalable for the length of time the pumps are run. Amarinth has already provided ATUs with tanks of working capacities in excess of 300 litres and greater capacities can be achieved within a scaled footprint. Manufactured from 316L stainless steel, meeting or exceeding all standard requirements, the Amarinth ATUs are fully ATEX compliant. Safety is paramount, and the ATUs come as standard with a non-return valve on the feed line to the seal system, pressure control valves to relieve excess pressure and a level transmitter in the tank to warn of low fluid levels.

The layout of the Amarinth ATU is designed with function and maintainability as the key parameters with carefully organised and consistent venting and drains throughout. An easily accessible basket strainer is provided with a differential pressure alarm to remind that filter cleaning is required. There is also an integral instrumentation sunshade to assist readability in bright conditions and to protect from solar temperatures. Safety equipment such as safety relief valves can also be included within the same layout allowing flexibility to suit a particular contract.

Drawing on its proven engineering agility and sound business processes, Amarinth is working with a select group of suppliers to achieve a lead time of under 22 weeks if the contract requires it. All components are from approved vendors ensuring the whole system is fully compliant with a customer’s requirements.

Oliver Brigginshaw, Managing Director of Amarinth, commented: “The recent increase in new pump orders we are experiencing is demanding ever shorter lead times and one of the longest lead time items in a system has been the ATU. By bringing the design and manufacture of these units in house and leveraging our proven skills in agile engineering, we have been able to make this breakthrough in design so that we can continue meet the evolving needs of our customers.”

Available for download in PDF format, simply click the button below to download.

Download FileNOTES TO EDITORS:

Amarinth is a carbon net zero organisation delivering world-leading expertise in the design, application and manufacture of centrifugal pumps and associated equipment for critical applications in many of the most arduous and hostile environments around the globe.

Founded in 2002, Amarinth has harnessed the skills, creativity and passion of people who have worked in the pump industry for decades, delivering bespoke API and ISO pumps primarily to the offshore and onshore oil & gas industries; nuclear and renewable energy generation; defence; desalination; process and industrial markets.

The company’s innovative approach, business agility and use of sophisticated computer applications enables it to deliver robust, reliable and sustainable pumping solutions on the shortest lead times in the industry.

• Process pumps – API 610, API 685, ISO 5199 horizontal, vertical and in-line bespoke process pumps, including ones that are hydraulically and dimensionally interchangeable with the former Girdlestone and other obsolete pumps.

• Skid packages and modules – Supplied with a variety of drives for applications including de-sanding, mixing, filtration and chemical injection and tailored for the oil & gas, water treatment and power generation industries.

• Condensate recovery – Cutting-edge design providing low NPSH up to 98°C with variable speed drives to reduce cycle time and lower operating costs, available in stainless steel, galvanised or copper tanks for light or heavy industrial uses.

• Seal support – Integrated pressurised and vented seal support systems designed and delivered to API 682 and ISO 5199 standards and specific site specifications and requirements, working closely with AES, Eagle Burgmann, John Crane and Protect System.

• Spare parts – Critical spares for all Amarinth pumps and related components can be dispatched the same day, reducing potential downtime, and in addition components for the former Girdlestone and other obsolete pumps can be re-engineered often improving the performance of existing assets.

• Services – A full range of pump related services, delivered from UK head office or on-site globally, onshore or off-shore, including full commissioning and start-up support; also strip, report and refurbishment of any pump regardless of manufacturer.

Amarinth operates globally from its base in Rendlesham Suffolk, United Kingdom and offices in the Middle East and Malaysia with a global customer base, including BP, Shell, ADNOC, NOV, ExxonMobil, Schlumberger, COSCO, EDF, GlaxoSmithKline, Saudi Aramco, Pfizer, Diageo, Kuwait Oil Company, AMEC, Fluor, LUKOIL, Halliburton, and Babcock.

For further information or photos contact

Comment:

Alex Brigginshaw

Commercial Director

Amarinth Limited

Bentwaters Park, Rendlesham

Woodbridge IP12 2TW

United Kingdom

Tel: +44 (0)1394 462131

Mobile: +44 (0)7703 681821

Alex.Brigginshaw@Amarinth.com

Media Relations:

Phil Harland

B6 Solutions Limited

29 Swan Drive

The Wharf, Aldermaston

Reading RG7 4UZ

United Kingdom

Tel: +44 (0)118 971 3271

Mobile: +44 (0)7880 748380

Phil.Harland@B6solutions.com