When Pakistan Petroleum Limited chose Ranhill Worley as its contractor for a USD 21M Engineering, Procurement and Construction project, Ranhill turned to Amarinth for the 10 bespoke pumping units required.

PPL laid down demanding requirements for the API pumps for its Adhi Gas Processing Plant II situated in the district of Chakwal near Rawalpindi. The pumps would deliver Liquid Petroleum Gas from the refinery to the bottling plant and would need to operate at very high suction pressure. In addition to the technical demands of the project, the equipment had to be acquired on the shortest possible lead-time to meet the critical path planning of the project, and they had to come from an ISO9001 accredited supplier. Many of the technical discussions between the equipment provider, the prime contractor and the operator had to take place across multiple time zones. The plant location had little infrastructure and so the pumps needed to operate with few services.

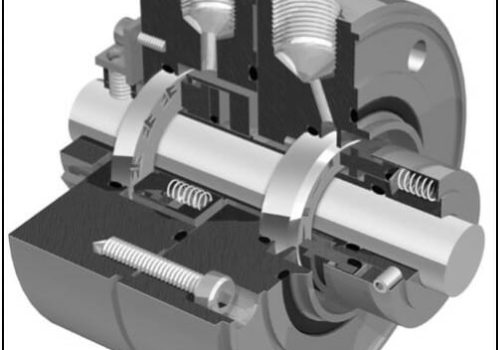

Laser faced single seals

Amarinth responded to the demands with an innovative and comprehensive technical offer. For the LPG and NGL process duties, Amarinth A-series API 610 pumps formed the basis of the bespoke design. Amarinth made changes to the standard pump design to enable it to cope with the resulting thrust from the high suction pressures. An unmodified pump used for this application would have suffered from excessive maintenance or ultimately failure due to the additional strain placed on the drive assembly. C-series ISO5199 pumps were chosen for the cooling water duties and T-series vertical sump pumps for the oily water drain duties. To simplify the scope of the project, Amarinth worked closely with specialist seal manufacturer John Crane to offer a laser faced single seal in all the pumps. The precisely laser-machined face designs of this seal prevent the entrapment of solids and enable the pump seal to handle the required pressure. The use of this technology was unique to Amarinth and removed the need for the additional pipework and buffer fluid systems services required by the alternative traditional double seal and Plan 53A Sealant System, thereby simplifying installation and speeding up the project implementation.

Reduced delivery times and costs

The use of laser faced single seals reduced the delivery time by 8 weeks and the cost of the solution by 20% compared to initial budgets. As the customer’s specification was finalised, Amarinth made their staff available 24 hours a day to offer advice through conference calls with Ranhill in Malaysia. This ensured that all engineering staff engaged with the project had the latest information to hand during their working day, thereby eliminating any delays that might have occurred. Based on the success of the PPL plant, Ranhill are now promoting the use of single seals in other applications to deliver cost and time benefits. Amarinth has also appointed Global Corporation as its local agent which is now handling commissioning and other technical details in the region. An additional pump has also been ordered.

Amarinth is independently verified by, accredited to or members of the following: