Can a more cost effective API 610 VS4 pump deliver the duty instead of a VS1 pump

FOR IMMEDIATE RELEASE – 31 July 2012

Time to think again about whether the more cost effective API 610 VS4 pump can deliver the duty instead of a VS1 pump

There are various types of vertical pumps available from VS1 to VS7, each of which suits a range of applications. Within the oil and gas industry the two most common API 610 vertical pumps employed are VS1 and VS4. Oliver Brigginshaw, Managing Director of Amarinth, a leading company specialising in the design, application and manufacture of pumps and associated equipment, explains why companies who have always specified a VS1 pump should think again about whether a more cost effective VS4 pump could meet the duty required.

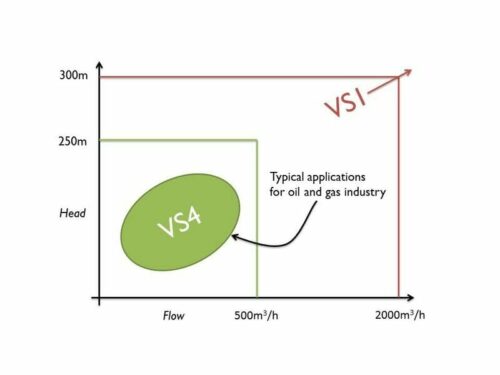

Within the oil and gas industry there are many engineers who continue to specify the well-known but complex VS1 pumps, more through historic reasoning than whether or not a much simpler VS4 pump may be adequate for the duty. VS1 pumps will always be suited to those duties that require high flow or head but for many applications a VS4 pump (with or without a booster pump) will perform the required duty perfectly well (see Figure 1).

Multistage VS1 pumps

VS1 pumps can be single or multistage and in theory can work to a limitless depth. VS1 pumps achieve this through the ability to have multiple stages stacked one on top of the other (see Figure 2). The fluid is pumped from the sump through the support column and out into a discharge bend. The sharp bend on the discharge however produces a loss in performance and a VS1 pump generally requires an expensive double mechanical seal and Plan 53 seal support system to prevent leakage.

The bearings of the shaft in each stage of a VS1 pump are mounted inside the support column by spiders. This works well for relatively clean fluids but where the fluid being pumped contains sand or grit, which is typical in oil and gas applications, wear of the spiders occurs. In addition, where sand or grit is present, VS1 pumps require an expensive seal support system to enable a clean flush to be fed to the bearings. The grease lubrication of the bearings in VS1 pumps is also expensive to manufacture and whilst all vertical pumps require removal from time to time, disassembly and reassembly of VS1 pumps is quite time consuming.

VS4 pumps overcome many issues

In comparison, VS4 pumps overcome most of these issues. In a VS4 pump the central column contains the drive shaft to the pump which is supported by a number of bearings depending on the length, but the pumped fluid exits via a separate discharge pipe running parallel to the column from the sump to the top plate which means it can pump the gritty fluid independently of the shaft bearings using various filtering techniques (see Figure 2).

There is no need for a complex mechanical seal at the top plate, usually just a simple vapour seal is required which costs significantly less than a double mechanical seal system. The discharge pipework can also be better designed to reduce losses.

The shaft bearings, sometimes also referred to as line bearings, in the VS4 pump can be easily lubricated and flushed, either by recirculating some of the pumped fluid (which can be filtered through strainers if sand or grit content is high) or using a separate clean fluid flush system should this be available on site.

VS4 pumps can also be built in stages allowing for the quick and easy removal for maintenance in areas of limited headroom. Where a higher flow is required, a VS4 can act as a booster pump with the main pump operating in series and feeding a horizontal centrifugal pump above ground which will then achieve similar head and flows to a VS1, but with the added advantage of maintenance to the horizontal centrifugal pump being much quicker and easier as it does not require lifting out of a sump before maintenance can commence.

Carefully consider whether VS4 will meet the requirements

There are definitely occasions where a VS1 pump must be specified, such as when there is not enough NPSH available to feed the pump, but increasingly customers are finding a VS4 pump can offer a cost effective and easier to maintain option than selecting a VS1 pump, even when an additional horizontal pump is brought into the equation.

If you have a requirement for a vertical sump pump and have to date only specified VS1 pumps, then consider whether a VS4 pump will meet your needs. If the VS4 pump can perform the duty, then they are less expensive, simpler and less costly to maintain than VS1 pumps, particularly if the fluid being pumped contains abrasive solids.

Available for download in PDF format, simply click the button below to download.

Download FileNOTES TO EDITORS:

Amarinth is a carbon net zero organisation delivering world-leading expertise in the design, application and manufacture of centrifugal pumps and associated equipment for critical applications in many of the most arduous and hostile environments around the globe.

Founded in 2002, Amarinth has harnessed the skills, creativity and passion of people who have worked in the pump industry for decades, delivering bespoke API and ISO pumps primarily to the offshore and onshore oil & gas industries; nuclear and renewable energy generation; defence; desalination; process and industrial markets.

The company’s innovative approach, business agility and use of sophisticated computer applications enables it to deliver robust, reliable and sustainable pumping solutions on the shortest lead times in the industry.

• Process pumps – API 610, API 685, ISO 5199 horizontal, vertical and in-line bespoke process pumps, including ones that are hydraulically and dimensionally interchangeable with the former Girdlestone and other obsolete pumps.

• Skid packages and modules – Supplied with a variety of drives for applications including de-sanding, mixing, filtration and chemical injection and tailored for the oil & gas, water treatment and power generation industries.

• Condensate recovery – Cutting-edge design providing low NPSH up to 98°C with variable speed drives to reduce cycle time and lower operating costs, available in stainless steel, galvanised or copper tanks for light or heavy industrial uses.

• Seal support – Integrated pressurised and vented seal support systems designed and delivered to API 682 and ISO 5199 standards and specific site specifications and requirements, working closely with AES, Eagle Burgmann, John Crane and Protect System.

• Spare parts – Critical spares for all Amarinth pumps and related components can be dispatched the same day, reducing potential downtime, and in addition components for the former Girdlestone and other obsolete pumps can be re-engineered often improving the performance of existing assets.

• Services – A full range of pump related services, delivered from UK head office or on-site globally, onshore or off-shore, including full commissioning and start-up support; also strip, report and refurbishment of any pump regardless of manufacturer.

Amarinth operates globally from its base in Rendlesham Suffolk, United Kingdom and offices in the Middle East and Malaysia with a global customer base, including BP, Shell, ADNOC, NOV, ExxonMobil, Schlumberger, COSCO, EDF, GlaxoSmithKline, Saudi Aramco, Pfizer, Diageo, Kuwait Oil Company, AMEC, Fluor, LUKOIL, Halliburton, and Babcock.

For further information or photos contact

Comment:

Alex Brigginshaw

Commercial Director

Amarinth Limited

Bentwaters Park, Rendlesham

Woodbridge IP12 2TW

United Kingdom

Tel: +44 (0)1394 462131

Mobile: +44 (0)7703 681821

Alex.Brigginshaw@Amarinth.com

Media Relations:

Phil Harland

B6 Solutions Limited

29 Swan Drive

The Wharf, Aldermaston

Reading RG7 4UZ

United Kingdom

Tel: +44 (0)118 971 3271

Mobile: +44 (0)7880 748380

Phil.Harland@B6solutions.com