To extract the remaining reserves in the oil and gas fields around the world requires engineers to break new ground to overcome formidable technical challenges.

In 2012 the UK Government announced the Brownfield Development Programme to encourage operators to get the very most out of existing fields and infrastructure in the UK Continental Shelf.

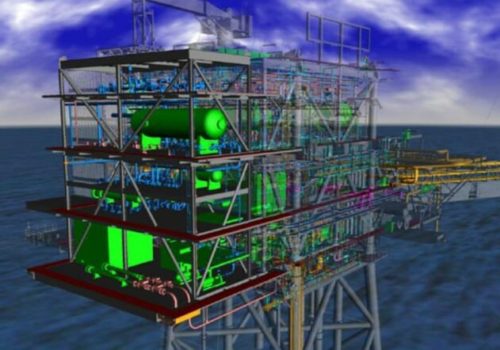

With help from this initiative the Alder platform situated in the North Sea will receive a new topsides package to enable the extraction of these hard to reach reserves.

When production starts in 2016 it is expected to build up to a design capacity of 110 million cubic feet of gas and 14,000 barrels of condensate (a light oil) per day.

High pressure and temperature

The Enhanced Oil Recovery (EOR) process that will be used to get the remaining oil out of the Alder field involves injecting water into the well at high pressure.

Following this process, the oil which is released will then be separated from the injected water when it comes up to the platform.

This separator recirculation process called for a number of API 610 OH2 A-Series pumps. The returning fluid is at a temperature of 85C and a pressure of up to 60 bar, which is outside the base specifications for API 610.

Not only is the process fluid at a high pressure but this pressure is not constant. The suction pressure at the pumps is expected to fluctuate between 1 and 60 bar.

Furthermore, these pumps and their seal support systems had to be designed to fit within the confines of the existing Alder structure, demanding a compact solution.

Uprated pump casing

To handle the 60 bar pressure, Amarinth designed and tested a new pump casing for its API 610 OH2 A-Series pump to a higher Maximum Allowable Working Pressure (MAWP) of 75 bar.

The seal support system required careful consideration. The usual Plan 53B seal support system used with these pumps is a fixed pressure system and so would have had to maintain a constant pressure of 60 bar to handle the peak pressure. Not only is this above the usual Plan 53B design pressure but the large fluctuations in suction pressure would have put undue stress on the system.

Amarinth is independently verified by, accredited to or members of the following: